As the greatest efficiency in handling your needs is our mission, VAER s.r.l. faces the market not as a simple supplier of molds or related products, but as a real business partner.

We assist the client during the whole process, starting from an initial idea to the serial production of single items, by speeding up the progression and giving adequate support.

To this purpose, VAER s.r.l. has modeled its internal structure based on the following criteria:

Idea

- Design and industrialization of single items, groups, systems

- Technical consulting, with special emphasis on the selection of materials, shape of the piece, surface finishing, tolerance, cost

- Supply of functional or aesthetic prototypes within short deadlines

Design

- Study and design of injection molds through 3D software (CAD)

- Filling analysis, casting simulation, deformation checks (CAE)

- 3D software creation for mill cutting and erosion (CAM)

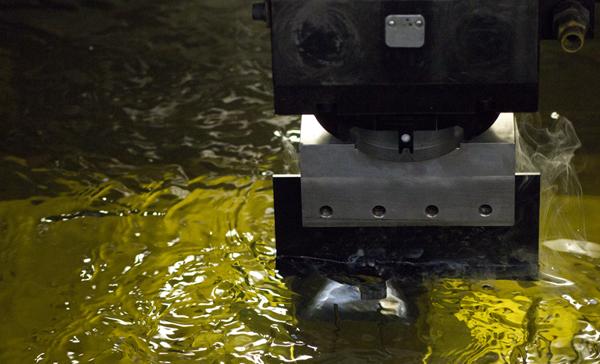

Mold

Mold manufacturing through all state-of-the-art technologies available:

- Traditional and high-speed CNC mill cutting

- Plunge and cable spark processing

- Rectification

- Traditional and deep pricking

- Laser Micro-incisions (with trusted partners)

- Laser Welding for mold restoration (with trusted partners)

Production

- until 1.000.000 pieces a year

- with injection press from 62 to 550 tons

- of details from 1 to 2.000 gr.

- used plastic material: Polymers (PS,PP), Technopolymers (ABS,PMMA.SAN,PC,PA,PO,PBT,PPO) Superpolymers (PPS,IXEF,PEI,PEEK), natural or reinforced (Reinforcement: microspheres, talc, glass fiber, carbon fiber; Lubricants: PTFE, silicone, graphite)

- Mold testing

- Sample lots casting

- Assemble

- Colour pad printing (with trusted partners)

- Painting

- Soft-touch covering (with trusted partners)

- Metal treatment